Tour to LEGO factory

All kids simply adore LEGO. This construction toy is played by millions of children all over the world and gives them joy, ability to develop logical thinking, invent new things, and spent many hours together with their parents, constructing different vehicles, vessels, airplanes, buildings, robots and mechanisms. It goes without saying, not only kids are fond of LEGO. A lot of adults are truly mad about it, spending their free time on their extraordinary hobby – LEGO collecting and building.

In 2004 I watched a wonderful movie on National Geographic TV Channel “MEGA FACTORIES: LEGO”. This is where my story begins. I’ve become curious in history and invention of this brand and everything what was connected to it. I studied the work of the company and their main processes inside the factory. Of course, pretty soon I came to the idea of visiting the LEGO factory. But what I found out – it was not easy at all.

During next two years I wrote hundreds of letters to LEGO Group directly as well as to its plants in Denmark, Czech Republic and Hungary. I could hardly believe it would be so difficult to get inside the factory to see the process of the famous construction toy production. There were about a dozen of people’s feedback about their visits of the Danish plant. Somehow they’d managed to get there and described their experience as something really incredible. After contacting a couple of those “luckies” I realized how far my dream is from me now. LEGO factory in a Danish city of Billund was open for excursions only three times a year. And in general during this time it was admitted by some “close” people. Other people said the price of a group tour is 1600 EUR. I didn’t give up and asked for help from other tour agents. But that didn’t make any sense. Everybody refused to find the way. One of them, nevertheless said, he’s to try to help me for 400 EUR, but couldn’t guarantee the success.

And one day at the beginning of 2016 a read news on a Hungarian web-site that the LEGO plant in Nyiregyhaza conducts excursions for schoolchildren. I spent two month on searching for the contacts of the company responsible or at least able to organize an excursion, but didn’t succeed again. I wrote messages to those who were there that time under their photos in Instagram and FaceBook. Nobody answered. I broke it up. For a while :) In 6 month I continued looking for a tour to the LEGO factory in Hungary.

Remember, if you desire something from all of your heart and are not lazy to find the way, finally you’ll succeed! Due to the support of Mr. Laszlo Vida the ambassador of the General Embassy of Hungary in Uzhhorod and Alexander Koval the chief executive of “Turinform Zacarpatye” my dream came true and we visited the LEGO factory in Nyiregyhaza. Read about our experience after a few facts about the LEGO Group.

The History of LEGO

The LEGO Company was founded by Ole Kirk Christiansen carpenter who lived in a town of Billund in Denmark in 1932. The company consisted only of carpenters and joiners first, whose duty was to create a toy to develop kids’ imagination and creativity.

LEGO – is an abbreviation of two Danish words “leg godt,” meaning “play with passion.” “This is our brand name and it completely reflects our ideal and our goal,” – as they say in the company. For 80 years of the its existence it went a long and difficult way from a carpentry workshop to an international company, which is world’s third company by the volume of toys produced.

LEGO Company moved from father to son’s ownership and now it belongs to Kjeld Kirk Kristiansen – founders great-son.

Ole Kirk Christiansen with son Gottfried Kirk Christiansen and grandson.

Ole Kirk Christiansen with son Gottfried Kirk Christiansen and grandson.

First LEGO toys were made of wood and have nothing in common with those bricks, we play with now. Along with wooden toys the company produced chairs, ladders, ironing boards.

Wooden duck on wheels, manufactured by LEGO in 1935.

Wooden duck on wheels, manufactured by LEGO in 1935.

First there were only 7 people in the company. They produced 42 models of toys. Things went well, but as a result of a short circuit in 1942 the whole plant burnt to the ground. All the stocks and drawings of new toys were destroyed. Ole Kirk even thought of finishing with this business, but pulled himself together and started from the very beginning.

In 1947 LEGO became the first company in Denmark which bought necessary equipment and necessary spare parts to work with plastic from that on. And soon in 1949 LEGO was producing more than 200 types of plastic and wooden toys and their parts in particular some were specified with an easy compatible mechanism which was the first appearance of a future mega-popular construction toy.

In 1958 a significant event happened – LEGO patented their special way of fastening parts named as stud-and-tube. Since then all the parts and details produced by LEGO were absolutely compatible with each other. You can take LEGO bricks produced in 1958 and those produced in 2017 – they would be 100% compatible with each. Amazing!

Now LEGO Group – is an international company with its production facilities in Denmark, Mexico, Czech Republic, Hungary and China. It employs 18500 people all over the world now.

LEGO Motto

«Det bedste er ikke for godt» – «Only best is worthy».

You know how it appeared?

When 12-years-old Gottfried Kirk, the son of the founder, boasted to his father, how much money he saved when covered the wooden ducks with only three layers of polish instead of three, his father was deeply disappointed and to spend all night on covering all those toys with an extra layer of lacquer, to make them corresponding the standards. The experience Gottfried got inspired him to commemorate the words of his father by carving them on a wooden tablet.

Interesting Facts About LEGO

- One can make 915 mln different combinations of 6 LEGO bricks 2x4.

- In average they sell 15 LEGO kits per 1 second in the world. On holiday time – about 50 kits per second.

- Around 600 bricks are produced at LEGO factories per second and every month the figure gets higher and higher. To some statistics the speed of production is up to 1300 bricks per second.

- The number of LEGO elements in different color is – 34703. The number of colors the elements are painted in – 136.

- Around 400 mln tyres are produced on LEGO plants annually, what makes LEGO the biggest tyres manufacturer in the world.

- LEGO plastic is heated to the temperature of 232 degrees Celsius during the production time. Thus it can be kneaded like a dough :)

- Billund Airport in Denmark was built by the founder of LEGO – Ole Christiansen.

- The first shelving for the Google Server was constructed of LEGO.

- Practically all the Lego minifigures are of yellow color.

- LEGO Group prohibits any mention of its trademark LEGO® in domains in the Internet.

- The quality of production is so high that only 18 bricks don’t meet the highest standard.

- Everyone can download on the website of “Lego” his idea of construction set and offer it for a serial production. If the model get 10000 of votes, the staff will consider it.

LEGO factory in Nyíregyháza, Hungary

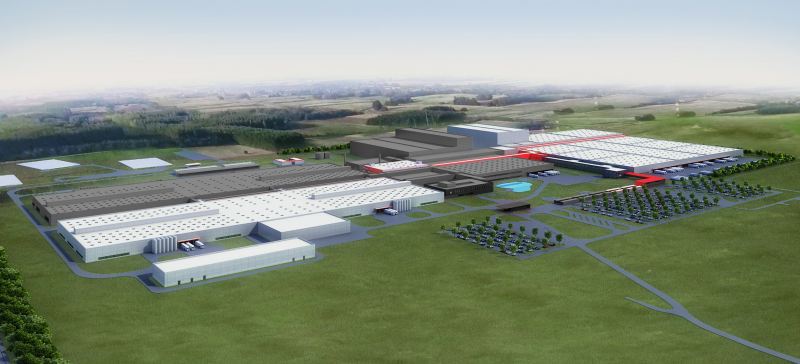

In 2014 in a Hungarian town of Nyíregyháza a new second LEGO factory was opened to manufacture bricks for construction kits LEGO® DUPLO®. It’s hard to believe such a huch plant was built within a year! The thing is that in 2008 one LEGO factory was already created on the other side of the city. But its capacity was not enough and the corporation decided to build one more factory to have a huge potential for expansion.

- At the factory of Nyíregyháza they produce and pack bricks for construction toys LEGO® DUPLO®.

- 2400 people work at the factory, mostly locals. The salary is average within the country, but the company provides good social care to its employees, as well as life insurance and bonuses. Such as: every employee can by a construction toy right at the factory with at a half of the market price.

- The factory occupies the total area of 120000 sq.m.

- 672 forming machines working under the pressure with plastics are set on the territory of 53000 sq.m.

- 16 packing lines.

- High warehouse with an area of 14000 sq.m. for pallets and boxes storage.

- Two high warehouses where 82000 pallets with ready products can be stored at one time.

Photo source: lego.com.

Photo source: lego.com.

LEGO Group development plans in Hungary

The company has grand plans and development strategy until 2020. They are to expand the territory of the factory in Hungary and make it twice bigger. It’s gonna be a mirror reflection. There is enough land around for such an idea. The number of employees will increase for 1600 people, depending on a season, so in total there will be more than 4000 people working.

Future plans:

- To expand the factory’s territory up to 290000 sq.m.

- To equip the common production area with 768 machines for casting.

- To add a new module for mold assembly.

- To build a new warehouse with storage facilities for 500000 boxes and 40000 pallets.

- To build a new packing hall.

- To build a new hall for rubbish and wastes sorting.

- To build a new administrative building.

- To build a new house for LEGO System elements processing and decoration.

- To build a new house for LEGO Duplo elements processing and decoration.

- To build a new building to control the whole factory energy consumption.

A visit to LEGO

At 5 a.m. our group was picked up by a minibus from the city of Uzhhorod to Nyíregyháza. It took us five hours to get there, including the time for crossing the border, but in fact the distance was less then only 100 km. Actually we spent quite a lot of time at the border. Remember, you should have a children seat if you go abroad on a minibus.

Hungary met us with a good weather as sunny, as our mood, because we were only a few steps away from our dream! After crossing the border the driver took the gps navigator and found the address of the factory. We should have been there in time according to the route at the gps. As we entered Nyíregyháza I’ve noticed an incredible amount of car sale expo-fields both new and old ones. So many of them!

Nyíregyháza is the sister town of Uzhhorod. It is the seventh largest city in Hungary. The citizens of Transcarpathia often come here for shopping, holidays and rest at thermal bathes. One of the best European zoos is also located here. But if you’re interested in visiting Nyíregyháza there is a special photo-report which would be very useful for you!

We saw a sign of the factory and the factory itself behind it. Everybody felt excited and the leader of our group hurried to learn how to enter the territory.

We saw a corporate color of the LEGO Group and several trucks which were possibly loaded with fresh-made construction toys. But… That was the wrong factory! I knew that there are two of them in Hungary, I had read it before. Nevertheless our driver new the address of only one – wrong LEGO factory. He had no idea how to find another one.

But luckily I had a maps.me app which works with offline maps without any network connection, what is extremely useful when you’re travelling and don’t want to pay for roaming. I highly recommend to install this application to your smartphone and always to have the freshest maps of the area you’re travelling to. Even in Ukraine, I always use it. It’s some kind of a Must Have for a modern person.

So, we found out that we had to drive 10 km in quite another direction, luckily there were no traffic jams that time.

And here we are! The right LEGO factory which was much bigger than the one we’ve seen before.

There was a huge parking area which was fully packed with vehicles. There were also special places for electric cars. I didn’t count the number of chargers, but definitely more than 10 or 20. And, of course, a special roofed bike rental was available, too.

Wow, they drive good cars here in “Lego” :)

So many interesting things here. I take out the biggest camera I have and head towards the entrance.

Next to the factory there is a street with the right name: Address: 15, LEGO Street, Nyíregyháza.

Main entrance at the LEGO factory.

Main entrance at the LEGO factory.

Not taken even a couple of shots I was told by the security man to hide my camera away and not to take any single shot more – it is strictly prohibited.

Why so?! I didn’t expect such rules. Well, we could do nothing but we agree with each other to try to remember everything we see without photos.

As we came by the right address we were met by our guide. A young fellow around 25 works here as a guide and shows everything at the factory included into a tour program.

First we were shown a 10 min movie about the safe instructions at the factory: about the place where you can and cannot walk and/or take pictures. We put our signatures in visitors’ register book, left our bags and headed from the main entrance to the main building of the factory.

50 m from the entrance to the main building is an area where you can take pictures, and I tried not to miss a chance a took a couple of pics on my phone.

See that yellow brick behind the glass wall? Guess what’s inside?

Right, Lego bricks are inside. Have no idea how much of them there are, but definitely - a lot. But there are even more such containers at the factory.

A view of the main entrance from the side of the main building.

Inside he got another brief instruction, were given vests: yellow for visitors and orange for the guide.

A previous group of school children left a mess after them :)

The excursion takes two hours. A cool interpreter from Hungarian by the name of Alexander followed us and we were extremely grateful for his participation and for all those interesting things he told us!

As photos are strictly prohibited there are no photos at all :(

Excursion to the LEGO factory. Let’s get started

First we were told a detailed story about the history of the LEGO company creation and explained everything on an example of a layout – a mini version of a plant under the glass.

This plant produces and packs LEGO® DUPLO® construction toys for kid from 1 to 5. The territory occupied by the factory is really huge. Pretty soon a new one will be built as a mirror reflection. It is already in progress.

Then we moved a little closer to the heart of production facilities, where we were shown a piece of history – brick-molding machine. Nearby there is a tank with a raw material for bricks. Amazing! The produce 80 000 000 LEGO elements per 24 hours here!

Photo by: nyugat.hu.

Photo by: nyugat.hu.

LEGO elements molding machines workshop

There are more than 600 machines of such kind at the factory!

Photo by: wibsiteLEGO Group www.lego.com.

Photo by: wibsiteLEGO Group www.lego.com.

That was the first workshop we visited. I was knocked out for at least a couple of minutes, that was awesome! Everything was organized on the highest possible level! The workshop was absolutely clean, air conditioned. Besides it was not very noisy there what was quite strange considering the number of machines. Each machine stamps the elements and fills containers for them. When this small container is full it is changed for an empty one by the employee and passes the full one to another workshop via the conveyor.

The whole factory is linked by the “net” of connecting wires put into special troughs. They are marked differently having a strict order of numbering. Fire alarm pipes with water are also here to cover the whole area of the workshop in case of need. The air conditioning system is made at the top of quality. In general I was completely amazed by this excellent well organized systems and their interconnection.

LEGO group information technologies department

To make all the corporate infrastructure work as Swiss watch, the work of project department, development department, production facilities, logistic department, analytical and financial departments should be somehow reconciled and interconnected. For this purpose they need a powerful computer system, which will be well maintaining and constantly modifying by a huge employee staff of IT department. Hungarian IT specialists are lucky as the LEGO factory of Nyíregyháza houses the headquarter of LEGO IT-division. They serve information technologies of their factories worldwide. There are 60 high qualified specialists in this department. Plus one more group of IT-specialists working with this particular factory. I wish you could see their cool office rooms! It’s an open space where there are not only desks and computers, but an incredible amount of construction toys.

In general there 2400 occupied at this particular factory. Although for 2 hours of excursion I’ve noticed quite a few people.

Lego testing

Testing department, or better to say a testing workshop is located in an isolated room. Here the employees check the quality of the elements. They watch and turn them around in hands and put into special tanks. The guide told us an interesting fact. There is a so-called “Head” test. The load capacity for taking off the head from the minifigure should be not less than 50 kilos.

Lego pack

Practically all the processes at the factory are automated, except one – plastic bags packing into cartons. As they say, it’s hard to do it automatically, as the size of the cartons constantly changes. So, it’s easier and even cheaper to do it with hands. But I can assure you, that those 5–6 people we saw working at the conveyor did it well and pretty fast without any problems. So, seems like they feel OK while doing this job. One person takes a disassembled carton box and makes it ready, the second person puts plastic bags with the elements inside into the carton box, the third adds some more bags and, if I’m not mistaken instructions, the fourth glues the box and sends farther, where one more employee pust 5–10 boxes with construction toys into a master-carton and sends to the next point.

The boxes may be branded for huge chain shops. For example we saw, how the toys were put into Tesco branded boxes for Christmas season.

Lego warehouses

All the LEGO products are stored in two high warehouses with a capacity for more than 80 000 pallets. The warehouses are really giant and soon the storage area will be doubled. The construction toys are sent all over Europe straight from these warehouses by trucks standing on the territory of the factory.

Lego factory canteen

After an interesting excursion we felt quite hungry and were offered to visit the factory’s food canteen, where employees have their meals. Well, it was a casual canteen, looked like a typical fast-food restaurant with a wide range of meals. In spite of many people were standing in line waiting for their lunch, we didn’t wait long, they were serving people very fast. In average it costs 2–3 euro to have lunch here. Quite reasonable prices, to my mind.

I’ve also noticed, that not all the employees buy food in the canteen. Maybe this is so, because it would be hard to find a place for all 2000 people at one time. But we also saw many areas behind the glass walls at the production facilities where the staff could have a bite and rest a little.

Then we had some free time to take pictures in a hall and outside by the factory.

At the reception desk. By the way, in Billund the logo of the company in the foyer is made of LEGO elements.

At the reception desk. By the way, in Billund the logo of the company in the foyer is made of LEGO elements.

Outside there are nice statues made of LEGO bricks.

This man can be easily met in many cities worldwide where LEGO is sold. We also saw him in Poland once.

And how do you like this Carpathian Hutsul?

Totally made of LEGO.

And, of course, special kind of Hungarian grey cows which are also bred in Transcarpathia.

That was an unforgettable excursion to the Lego factory, which we will remember for a long time.

LEGO Group made a movie to its 80th anniversary telling the history of the company. Suggest you to watch it with your kids!

This tour was also made to develop the trans-border tourist route of Transcarpathia (Ukraine) and Szabolcs-Szatmar-Bereg (Hungary), due to the help and promotion from the side of General Embassy of Hungary in Uzhhorod and particularly Mr. Laszlo Vida. We’re also grateful to a tourist information source TourInformZakarpattya represented by Mr. Koval Alexander for the tour organization.